Have you ever imagined a virtual version of the real world that mirrors every detail and responds in real-time? Welcome to the fascinating world of digital twins! Explore how cloud-based digital twins transform the IoT industry and open up new possibilities.

- What is Digital Twin Technology?

- What are IoT Digital Twins?

- 8 Key Components of Cloud-Based Digital Twin Technology

- How Cloud-Based Digital Twin Technology Works in IoT?

- Applications of Digital Twins in the IoT Industry

- Why Choose Cloud-Based Digital Twins for IoT Devices?

- IoT, Edge Computing, and Digital Twin Technology: A Perfect Match for Innovation

- Key Statistics on the Impact of Digital Twins in Various Industries

- Future of Digital Twins and IoT Working Together

- Conclusion

The Internet of Things (IoT) has connected the world like never before. IoT devices gather data from smart homes to advanced factories to make systems intelligent. However, managing these systems can be challenging. That’s where digital twin technology comes in. It creates virtual replicas of real-world objects and improves their work efficiency.

Combine this technology with the power of the cloud. The result? An innovative tool that improves performance for anything connected to the Internet. It’s the ultimate blend of physical and virtual worlds working together to create more powerful systems.

Want to know about how digital twins fit into this IoT picture? Let’s make sense of it all!

What is Digital Twin Technology?

A digital twin is a virtual replica of a physical object, system, or process that exists in the digital world. Thanks to data collected by sensors, it doesn’t just look like the real thing but behaves like it.

Imagine a virtual twin of a real-world object, like your car. By continuously updating itself with real-time data from your car’s sensors, this digital twin knows when a tyre needs more air when it’s time for an oil change, or even how to boost fuel efficiency. It’s like having a tech-savvy co-pilot always watching out for you.

What are IoT Digital Twins?

IoT devices act as a digital twin’s senses: the eyes, ears, and touch. They gather real-world data, such as temperature or motion, and send it to the cloud. The digital twin then uses this data to create a live, virtual version of the IoT device it represents.

This virtual model replicates, learns, and adapts. It can predict issues, optimize performance, and suggest improvements by mirroring the real-world object.

Let’s understand this with a real-world analogy. Imagine a smart city equipped with IoT sensors on its roads. These sensors monitor traffic flow, vehicle speeds, and congestion levels. The city’s digital twin analyzes this data in real-time and suggests adjustments to traffic light patterns. This helps reduce traffic jams and shorten travel times, allowing the city to move more freely.

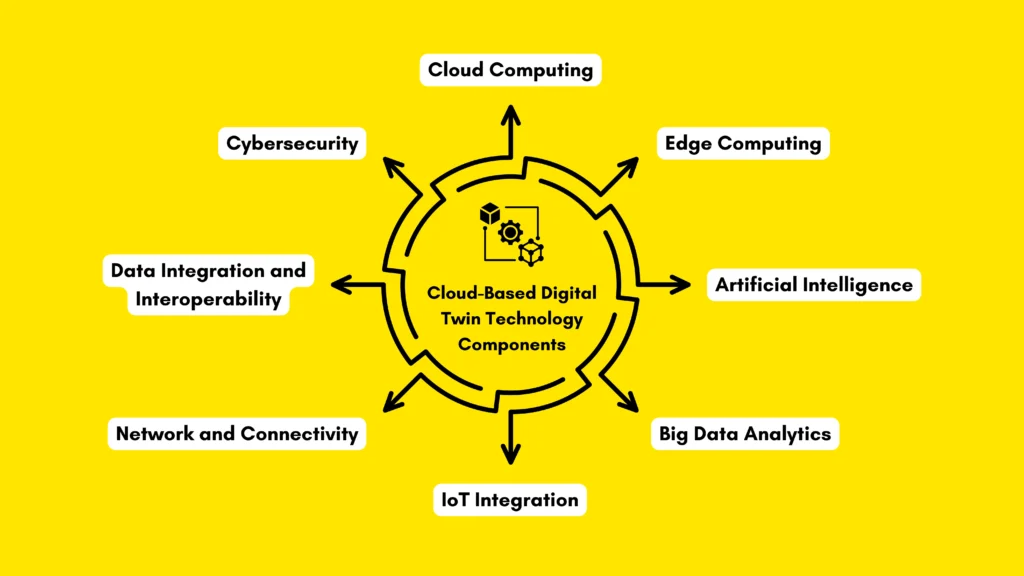

8 Key Components of Cloud-Based Digital Twin Technology

Digital twins depend on a strong framework of interconnected technologies. These components work together to create powerful virtual models. Let’s explore the essential ones that bring cloud-based digital twins to life:

- Cloud Computing: The cloud provides the storage and computational power to process huge amounts of IoT data. It hosts data analysis applications for digital twins that can easily scale up for larger operations. Cloud computing also allows digital twins to be accessed from anywhere in the world through the Internet.

- Edge Computing: While the cloud is powerful, sometimes speed is everything. Edge computing processes data locally, right where it’s collected, reducing latency and enhancing response time.

- Artificial Intelligence: AI makes digital twins truly intelligent. It processes real-time and historical data to spot patterns, predict failures, and even suggest improvements. AI’s learning capabilities also help digital twins evolve over time, becoming smarter as they interact with more data.

- Big Data Analytics: IoT systems generate massive amounts of data, which digital twins rely on. Big data analytics tools simplify this flood of information and extract meaningful insights. The more data analyzed, the better the decisions digital twins can make.

- IoT Integration: IoT sensors constantly monitor physical systems. These tiny devices collect data from these systems and send it to the cloud. This constant flow of information keeps digital twins accurate and up to date.

- Networking and Connectivity: A strong connection is essential for real-time applications. High-speed networks like 5G keep everything connected, establishing faster data exchange between physical devices and digital twins. This connectivity makes real-time operations possible in digital twins.

- Data Integration and Interoperability: Digital twins don’t operate in isolation. They rely on data from multiple sources, such as IoT devices, databases, and software platforms. Interoperability ensures that all these systems communicate well, creating a unified data-sharing and analysis environment.

- Cybersecurity: In digital twin technology, security is non-negotiable because so much data is involved at every step. Real-time threat detection protects sensitive information, keeping digital twin operations safe and secure. In a nutshell, from encryption to multi-factor authentication, every layer of protection matters.

How Cloud-Based Digital Twin Technology Works in IoT?

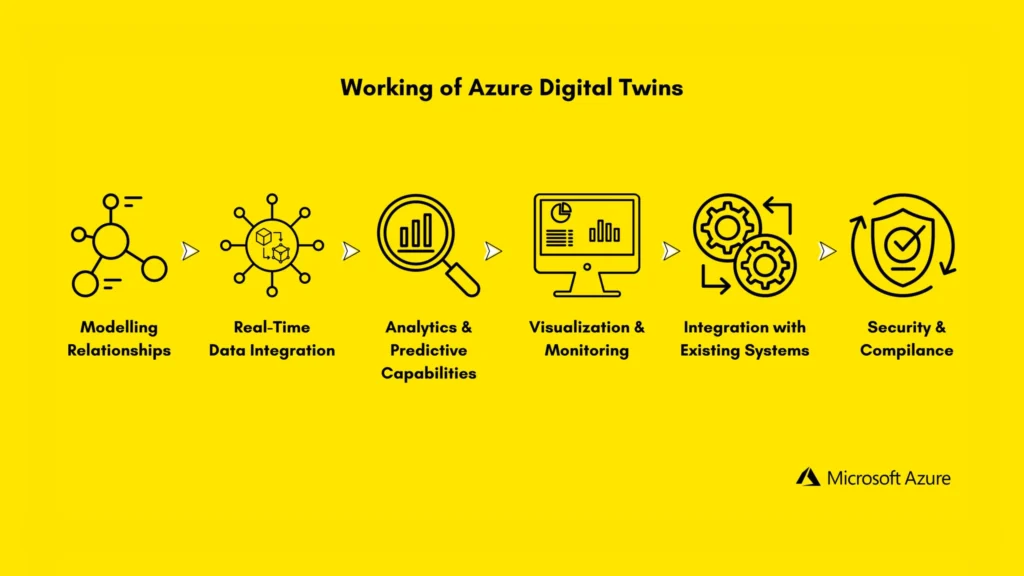

Microsoft Azure Digital Twins is a leading Digital Twin as a Service that helps businesses utilize the full potential of digital twin technology.

Let’s see how Azure Digital Twins work, along with Azure’s different tools for managing digital twins.

- Modelling Relationships: Azure Digital Twins uses a “Digital Twin Graph” concept to model real-world assets and their relationships. Mapping relationships creates a connected view of everything in digital twins’ operations.

- Real-Time Data Integration: Azure Digital Twins directly connects IoT sensors, cameras, and devices to digital twins, ensuring that the digital models are constantly updated with real-world information. Azure IoT Hub and Azure Data Explorer are key tools for keeping the data flow in sync.

- Advanced Analytics and Predictive Capabilities: Azure Digital Twins uses machine learning tools like Azure Machine Learning to analyze data and predict what might happen next. For instance, predictive maintenance can identify when equipment is likely to fail for proactive maintenance.

- Visualization and Monitoring: Azure offers interactive tools like Power BI to visualize digital twin data. These tools let users simulate changes in digital twins and instantly see the potential outcome, enabling better decision-making.

- Integration with Existing Systems: Azure Functions easily integrates digital twins with other systems, like ERP and CRM tools. This means that digital twins’ data becomes centralized, improving team collaboration.

- Security and Compliance: Azure Digital Twins ensures that all data of virtual assets is protected, meeting global standards for industries that require high levels of compliance, like healthcare and finance.

Applications of Digital Twins in the IoT Industry

According to a report by Fortune Business Insights, the global digital twin market was valued at $12.91 billion in 2023 and is projected to reach $259.32 billion by 2032. This exponential growth reflects the rise of digital twins across various industries.

Below are some notable applications of digital twin technology across various industries within the IoT sector:

- Healthcare: Surgeons use digital twins of organs to simulate surgical operations. Using data from IoT devices, these simulations allow for safer and more accurate procedures. For instance, Philips’ IntelliSpace Cardiovascular platform facilitates surgeons’ creation of heart digital twins for better patient care.

- Manufacturing: Automakers like BMW and Toyota use digital twins to simulate new assembly line setups before making actual changes. It helps them to test configurations, fix problems, and improve operations using real-time data from IoT sensors in their machines.

- Energy: In solar energy, digital twins analyze weather data to tilt solar panels for maximum sunlight. For instance, General Electric (GE) uses digital twins to optimize wind turbines, achieving up to 25% higher energy output. Similar techniques are applied in solar farms to enhance energy efficiency.

- Logistics: Fleet management solutions like those from Pivotal or Geotab use digital twins to monitor vehicle health. IoT sensors provide real-time data, allowing managers to predict maintenance needs and reduce downtime.

- Construction and Real Estate: Digital twins are changing how we manage infrastructure by providing live health monitoring. Arup, for example, uses them to proactively plan repairs and enhance building safety.

- Automotive: Companies like Tesla use digital twins of electric car batteries to analyze their performance in different environments. By using real-time IoT data, these virtual models help extend battery life and improve overall reliability.

Why Choose Cloud-Based Digital Twins for IoT Devices?

Cloud-based digital twin technology is changing the way companies interact with their IoT devices. It offers key benefits that lead to better operational strategies. Here are some of the main advantages:

- Enhanced Collaboration: Data from digital twins is usually available to all team members concurrently. The cloud allows multiple users to collaborate and share insights regardless of location. This leads to more informed decision-making.

- Real-Time Monitoring: Digital twins constantly monitor IoT devices. The cloud ensures that this real-time data is continuously stored and updated, allowing businesses to track the status of their devices at all times.

- Predictive Maintenance: By analysing huge amounts of IoT data, digital twins can predict when a device or system might fail. This data can be processed quickly in the cloud, providing more accurate predictions for companies to act swiftly.

- Cost Savings: Cloud infrastructure makes it easy to run simulations for digital twins at a lower cost. It eliminates the need for expensive hardware or extensive physical testing.

- Scalability: As businesses expand and add more IoT devices, cloud-based digital twins can scale easily with them. The cloud infrastructure ensures the system can handle increased demand without needing significant updates.

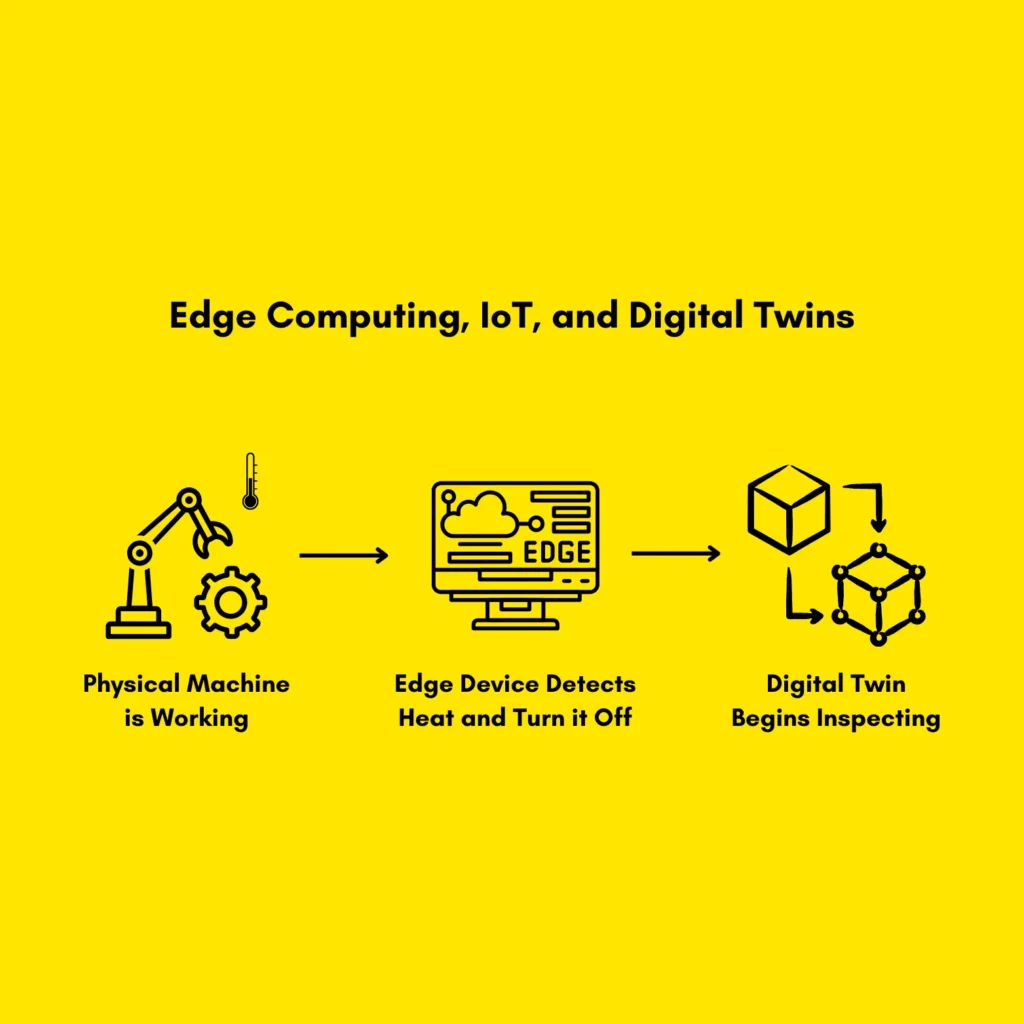

IoT, Edge Computing, and Digital Twin Technology: A Perfect Match for Innovation

Edge computing and digital twins are powerful combinations that make IoT systems much faster. They process data closer to where it’s collected, such as on a factory floor, reducing delays because not all data needs to travel to the cloud.

Imagine a machine on the factory floor that starts to overheat. The edge device can quickly sense the temperature rise and immediately shut down the machine to prevent damage. This quick decision happens right there, in real-time, without having to wait for cloud processing.

The digital twin takes over after the edge computing system shuts down the machine. It analyzes the root cause of the overheating issue, which might be a malfunctioning fan or incorrect settings. The digital twin uses this data to suggest fixes and prevent similar problems from occurring again.

Key Statistics on the Impact of Digital Twins in Various Industries

Cloud-based digital twin technology is making waves across industries; the numbers speak for themselves. The latest surveys and reports reveal how organizations are using this innovative technology to boost performance, cut costs, and achieve sustainability goals.

Here are some of the most striking statistics that highlight the real-world benefits of digital twins:

- Market Growth: 42% of executives from various industries see the value of digital twins, and nearly 59% plan to adopt them in their operations by 2028. (Source: Business Wire)

- Efficiency Gains: Manufacturing companies report a 15% improvement in operational efficiency and 25% performance gains. (Source: Capgemini)

- Sustainability Impact: Digital twins help buildings reduce carbon emissions by as much as 50%, playing a key role in boosting sustainability and energy efficiency. (Source: Astute Analytica)

- Cost Savings in Oil & Gas: Digital twins have helped reduce unexpected stoppages by 20%, saving up to €3.03 million per rig monthly. (Source: Astute Analytica)

- Smart Cities: Chattanooga, TN, improved traffic flow by 30%, reducing delays and enhancing energy efficiency using digital twins. (Source: Capgemini)

Future of Digital Twins and IoT Working Together

The future of digital twins and IoT is filled with endless possibilities. Digital twins are becoming smarter with AI and more integrated with IoT. They’ll power self-driving cars, smart cities, aerospace and aviation, construction and infrastructure, and much more. By combining IoT, AI, and the cloud, we’re building a world where digital replicas help us solve real-world problems faster and smarter.

Experts believe that by 2035, digital twins will become so advanced that they can simulate entire ecosystems. Imagine combining these digital worlds with IoT sensors. It could help scientists study climate change, protect endangered animals, or predict natural disasters without harming the environment.

Conclusion

Cloud-based digital twins are changing the way we interact with IoT devices and systems. By creating virtual versions of real-world objects and connecting them to the cloud, businesses can improve productivity, predict issues before they happen, and make smarter decisions. This technology is already making a big impact in healthcare, manufacturing, logistics, energy, and more, and the possibilities for its future are limitless.

Whether you’re looking to improve operations, reduce costs, or enhance customer experience, digital twins offer a powerful solution to help you reach your goals faster and more effectively.

The journey is just beginning, and we’re only scratching the surface of what digital twins and IoT can achieve together. The future is digital, and it’s smarter than ever!